GAZCOM technology for gasification of organic raw materials

GAZCOM technology for gasification of organic raw materials

Brief description of the method and variant of the Energy Center based on it, patents

Existing biomass gasification technologies, using mainly fireless pyrolysis, are focused on obtaining high-calorific gas with subsequent purification technology. All of them have in the composition of the resulting product – synthesis gas, liquid fraction and ash, a large amount of resins and toxic components. Gas cleaning and ash disposal make these projects economically unprofitable.

But we went the other way, our priority was not the calorie content of the gas, but its purity. With the complete combustion of any organic matter, incl. biomass, carbon dioxide (CO2), water vapor (H2O), nitrogen and its compounds (NOx) and a small percentage, but a number of others, are formed, incl. harmful components, the composition of which depends on the raw materials used. Having restored the main products of the combusted raw materials to CO, H2 and N2, passing them through hot carbon, we get a gas with sufficient calorific value for its combustion.

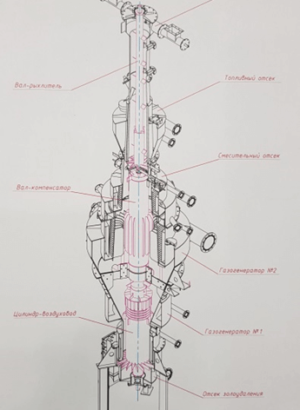

The uniqueness of our technology lies in the combination of known chemical reactions into a certain sequence, through a special double process of oxidation and reduction of combustion products. First (in the first reactor), from the raw material to be gasified, which has a sufficient percentage of carbon, we obtain active semi-coke, which is an active reducing agent in a heated state and an excellent adsorbing and filtering material in a cooled state, and then, with all its accompanying impurities, we burn it to ash (in second reactor).

The resulting dirty gas is not emitted into the atmosphere, as it usually happens, but we launch it into the head of the process, i.e. back to the first reactor for reburning. And after its repeated recovery, we pass it for cleaning through the active semi-coke already prepared for this purpose (between the first and second reactors), after which we remove it from the gasifier for transfer to consumers.

Such a trick has other advantages, for example, by directing this dirty gas, which has a temperature of around 200 degrees, not into the combustion zone of the first reactor, but higher, into the feedstock shaft, to dry it. This makes it possible, without any additional costs for the preliminary drying of the feedstock, to use raw materials with a moisture content of up to 60% at the inlet before gasification.

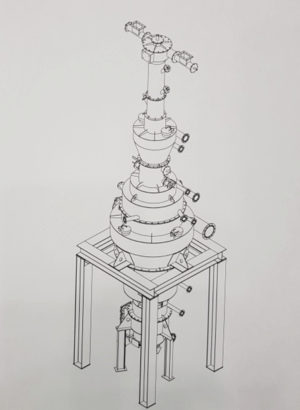

Gasificator ГУК

Ukrainian patent

Description of the patent

Eurasian patent

Video materials

Presentation for investors and partners

Gasification of solid organic raw materials, including biomass, RDF and other waste

The project provides for the construction of Energy Centers, consisting of a raw material preparation system, a gasifier with its infrastructure and cogeneration modules for generating electricity and heat, as well as, if necessary, the production of cold from heat, food carbon dioxide from exhaust gases, activated carbon and other demanded organic products.

The gasifiers used in these Energy Centers are designed to convert the chemical energy of various types of solid organic fuel into the chemical energy of generator gas: (CO – 28÷32%, H2 – 20÷24% and molecular nitrogen N2 – 46÷48%).

Gasifiers have the following requirements for the composition of raw materials: lower calorific value of at least 1800 kcal/kg, carbon content of more than 28%, humidity of less than 50%, ash content of up to 40%. This requirement is met by almost all organic substances, including biomass: wood chips, agricultural and livestock waste, sludge, etc.

In addition, as a possible addition to carbon raw materials, in the amount of 5 – 15% of its mass, hazardous waste can be disposed of: plastic, plastic bags, poisonous substances, herbicides and pesticides, waste from the medical field, waste and expired products of the pharmaceutical industry etc. Practically any chemicals and in any state: solid, liquid or gaseous, which are disposed of by their thermal decomposition at temperatures up to 1300°C, can be destroyed in an environmentally friendly way, in our gasifier. Also remarkably gasified is RDF (combustible residue of landfill sorting), which millions of tons have accumulated in Europe today in the sludge, are waiting for an environmentally friendly technology for their processing.

Energy centers based on biomass gasification

Feedback

Send your message and our manager will call you back as soon as possible